Standard Preventive maintenance procedure

The Instrumentation preventive maintenance is one of the standard procedure carried out in all industry regularly to prevent upcoming failure. The frequent inspection of instruments as is carried out during PM work reduces the break down significantly. The instrument in the process line is affected by surrounding process condition like dust, pollution, oil and other process liquids. By doing PM activity they are removed in short span regularly preserve the life time of the instrument. In case the PM work is not carried out then the process fluid exposed may not be noticed and lead to failure of the instrument at some point of time, the time and cost are wasted in production.

Important steps

*Make sure to get approval from the relevant department before starting the work.

* The analog input and digital input signal instrument has to shift from auto mode to manual mode before starting the work.

* The trip logic related to the tag has to be bypassed and need to record the action to get notified by other employers.

*The process will be isolated by the relevant department before starting the work. And recheck whether the line is de-pressurised and free from other harmful substance. Use proper PPEs for your safety.

* First clean the instrument throughout accumulated with dust and process liquids.

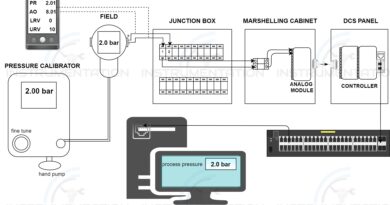

* Check the cable termination, cable landing and tightness of the cable from field to marshalling cabinet.

*Inspect the internal and external parts of the instrument for the damage that occur due to corrosion, rust, moisture etc.

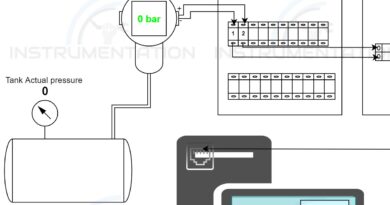

*Undergo calibration procedure to check the functionality of the instrument. If any error occurs correctly it as per the standard. And record the activities in the report for future reference.

*Check the open/close operation of instruments like a control valve, MOV, other on/off valve etc from DCS or manually by injecting signal. And if any problem occurs correct it.

*Instrument like a limit switch, proximity sensor etc the contact change over has to be checked by manually activating it and check the healthiness of every contact using the multimeter. And check the respective feedback in the DCS.

*And check for any leakage in fitting connected to the instrument and arrest it.

* Check the proper earthing and glanding of instrument without fail.

*The configuration and setting of the controller and other similar instruments have to be cross-checked with the standard value.

Conclusion

*After completing the pm work covers the instrument to enhance it’s protection against physical damage.

*And inform the operation department and take the loopback in normal mode. Remove the bypass is activated and note down in the register.

*Record all the activities in the checklist and save the report for future reference.

These are some of the useful steps help you to undergo Instrumentation preventive maintenance with guidelines of the standard procedure followed in your organization.