Pump interlock

It is one of the major pieces of equipment in any industry as for continuous processing the process fluid needs to be transferred from one place to another by the means of a pump. The pump helps to increase the pressure of the process fluid according to the capacity to fulfill process requirements. In order to safely start and stop the pump interlock is designed to serve the purpose. In this article, we will discuss the basic interlock used commonly in most pumps. Take a look at the picture below to get an idea of how pump interlocks is designed.

Source Level

The level of the fluid in the source should be adequate in order to pump fluid continuously. The low level may lead to running the pump in an empty load, so level transmitters or switches are used to safely stop the pump in case of a low level. And also only the pump will start if the level is normal.

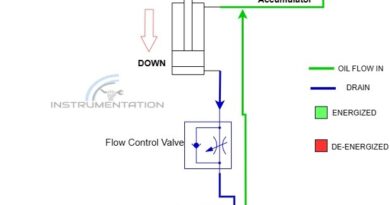

Pump interlock for valves

In certain conditions, valves are interlocked to open or close. For example, before starting the pump outlet valve should keep closed to avoid the hammer of the discharge line. So after the pump generates the pressure it’s gradually opened. And inlet valve should be kept open before starting the pump. And many interlocks are used for different kinds of valves for safe operation.

Vibration pump interlock

For any rotating equipment vibration is one of the important parameters to be monitored to protect the equipment from damage. The vibration is caused due to unbalance, poor alignment, etc. In such cases the safe vibration limit is given by the manufacturer of the pump, we shouldn’t run the pump above that limit.

Temperature Protection

The temperature of bearing along the drive and non-drive end of both pump and motor are monitored to immediately address the issue along the bearing. And also the motor winding temperature are monitored to find the problem in motor by observing the temperature rises.

Recirculation protection

As you see in the image the discharge line of the pump is connected back to the suction source. They are used to regulate the flow or pressure according to the process design and act as a protection.

And also several other instruments line pressure , temperature gauges , Dp switch etc for additional monitoring and protection purpose. Thus i hope you have gain some information regarding the pump interlock.