Pressure transmitter calibration procedures

This kind of question you will face in an interview as a starter in this profession. The reason for such questions is to check whether you are aware of the safety regulations followed in the industry. So before jumping in to answer the pressure transmitter calibration. explains the procedure you will follow in your industry before starting work. The work permit is one of the standards followed in all organizations to ensure safety. So start the work after applying for a proper permit. It’s also important to inform the field operator before starting the work. They will conduct the following isolation required to start the work.

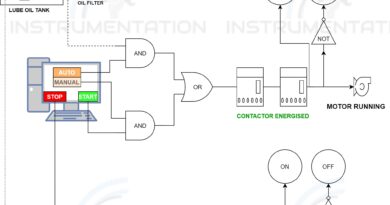

After the field operator, given clearance to work confirms with the Dcs operator whether any interlock available and tells them to force the tag you gonna work. Also, more importantly, use proper PEPS to ensure your safety all the time throughout your work inside any industry. Now let us start the calibration procedure.

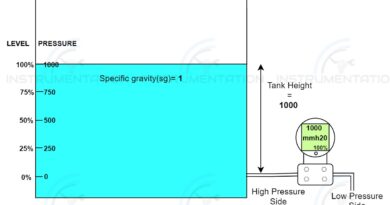

Calibrating a pressure transmitter can be done in several ways, we can remove the transmitter and take it to a laboratory to calibrate using a deadweight tester or we can use a hand pump type calibrator to inject pressure in the field. Select any method according to the instruction of your official. Let us consider your going to calibrate a pressure transmitter of range 0 to 100 kg.

1.After removing the vent valve of the transmitter checks the zero value, if it’s ok starts the five-point (0,25,50,75,100%) calibration procedure.

Undergo calibration in both forms rising and falling. Note down reading in the calibration report.

2.Apply 25kg/cm pressure to the transmitter. Check whether the transmitter is reading exactly or not and verify the multimeter reading. Note down reading in the report.

3.Similar inject 50,75 and 100 kg/cm2 pressure to the transmitter and enter respective multimeter reading in the calibration report.

4.Without releasing the pressure slowly reduces the pressure in the calibrator to undergo the falling method. Now set the pressure to 75,50,25 and 0 kg/cm2 and note down the pressure and respective current reading in the report.

5.If the error is under the limit given by the manufacturer then the calibration is completed. If it’s above the limit undergo zero trim of the transmitter using a hart communicator. After that repeat the calibration step to ensure the error is eliminated.

After completing the calibration, it is important to paste a calibration sticker to identify the next calibration date. Make sure the calibration sticker data will not get erased as days passed. After fixing the transmitter back to the process line. Inform the operator and close the work permits.