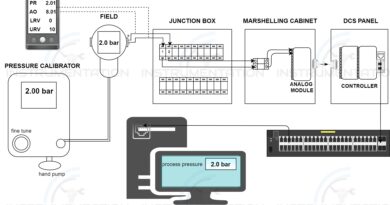

Pressure Transmitter Troubleshooting

The pressure transmitter troubleshooting is the common practice undergoes in any industry, as there are many tank, vessel, pumps available. The pressure measurement play as major role in controlling the process. Some of the points bellow will helpful in pressure transmitter troubleshooting.

*Even after isolating the manifold in the transmitter value is showing in the display. Then there may be passing in the manifold. Close the isolation Valve taken in the process line to check the status.

*The high pressure and low-pressure side of the transmitter have to be connected to the hp and Lp side of the transmitter respectively. If it gets interchanged then the transmitter will read a negative value.

*The equaliser in the manifold has to be Kept close while the transmitter is online. If its not closed properly then The pressure will get compensated through hp and Lp side. Hence the transmitter will read less value compared to the actual reading.

*The DP transmitter is commonly used in Level and flow measurement. In level measurement of open tank the HP side of the transmitter is connected to the tank. And Lp side of the tank is left open to atmosphere. In such case if the Lp side of transmitter get Blocked by dust or other process condition. Then the transmitter will display level greater than actual. And the wrong level will lead to inadequate process control.

*If the transmitter display is off while online. Then the possible failure are.

- The display may be faulty.

- If the polarity is interchanged

- The cable may be damaged at any point of the loop.

- The terminal may be loosened or the cable leg not properly punched, lead to a disconnect of the loop.

- The Analog input module may be faulty.

- The barrier may be opened or faulty.

*The transmitter has to be selected above the withstand temperature and pressure condition. If the parameter exceeds the limit then the error message will be displayed with a specific code. Every manufacturer has a different set of error code refer to the manual to find the error description.

*If the pressure value reaches above or below the range the output signal will be below 4mA or above 20 mA. This may lead to a display of bad value in the SCADA display.