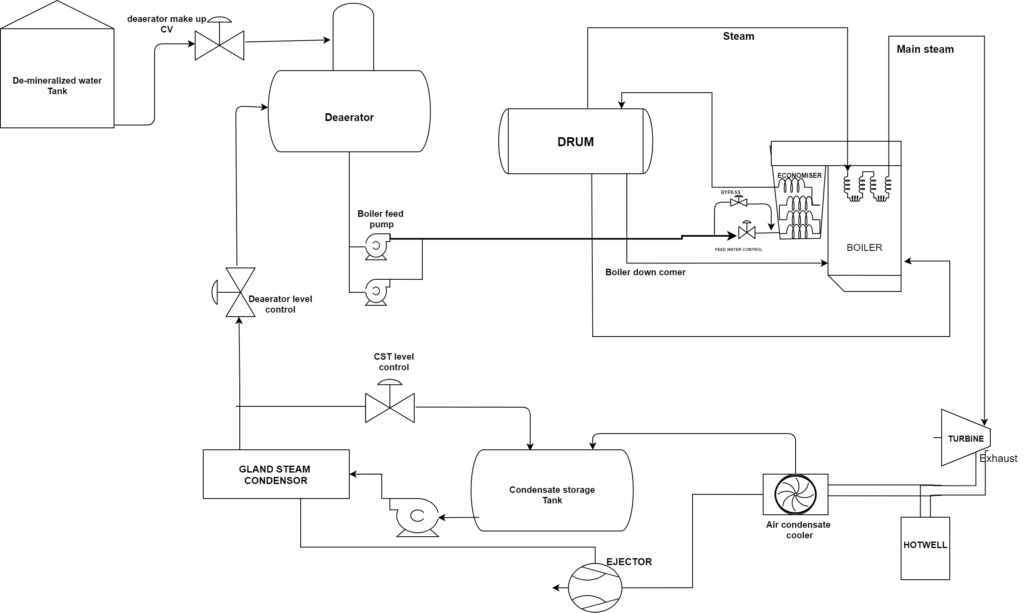

Power plant water and steam cycle

In a thermal power plant tones of water is used daily. To avoid water wastage they are reused in a possible way to preserve the environment. The water passes through several stages in any conditions and keeps on recirculating to produce electricity. The equipment involves in this process are given below.

- Demineralized Plant

- Deaerator

- Boiler Feed Pump

- Economiser

- Drum

- Hotwell

- Air condensate cooler

- Condensate storage tank

Demineralized Plant

The water before feeding into the boiler must be free from conductivity. In the DM plant, the water is processed in several stages to remove the ion in it. As it may lead to corrosion of tube in boiler and other effects. So it’s continuously monitored for water quality throughout the process. And the prepared DM water is stored in a tank is transferred to the deaerator by the level control valve.

Deaerator

The main purpose of the generator is to remove the dissolved oxygen from the water. The deaerator is designed in such a way able to appeared the oxygen by applying steam. The dissolved oxygen will get separated and get exhausted. And a chemical dosing is given to the discharge line before transferring to the boiler. Commonly hydrazine is used to regulate the DO content in water.

Boiler feed pump

The discharge water from the deaerator is pumped by the BFP to desired pressure before injecting it into the boiler. The pressurised water is passed to the feedwater control station. And the pressure is control as per load requirement.

Economiser

The water from the feedwater control station is transferred to the economiser. The water temperature is increased by exchanging with the outgoing flue gas. Hence the efficiency of producing steam is increased before injecting into the boiler. And the outlet is passed into the steam drum to maintain the level.

Drum

The drum is the place where water and steam get separated. And Drum level control is one of the important parameters monitored throughout the process. The water passed into the wall tube of the boiler through the downcomer line taken at the bottom of the drum. And the steam generated is transferred again to the drum. And the steam separated is passed into superheater stage before passing into the turbine.

Hotwell

The steam after hitting the turbine all stages has to be recycled. The exhaust steam is pulled out by the ejector and routed to the ACC. And some amount of water gets condensate will flow to the hot well. The hot well level is an important parameter as it has to maintain.

Condensate storage tank

The water after cooled by the ACC get passed to the CST. The CST tank store all the condensate water without wasting it. And the level of the CST is maintained by a level control valve taken from the discharge of the ejector pump.