Thermal Power plant basic

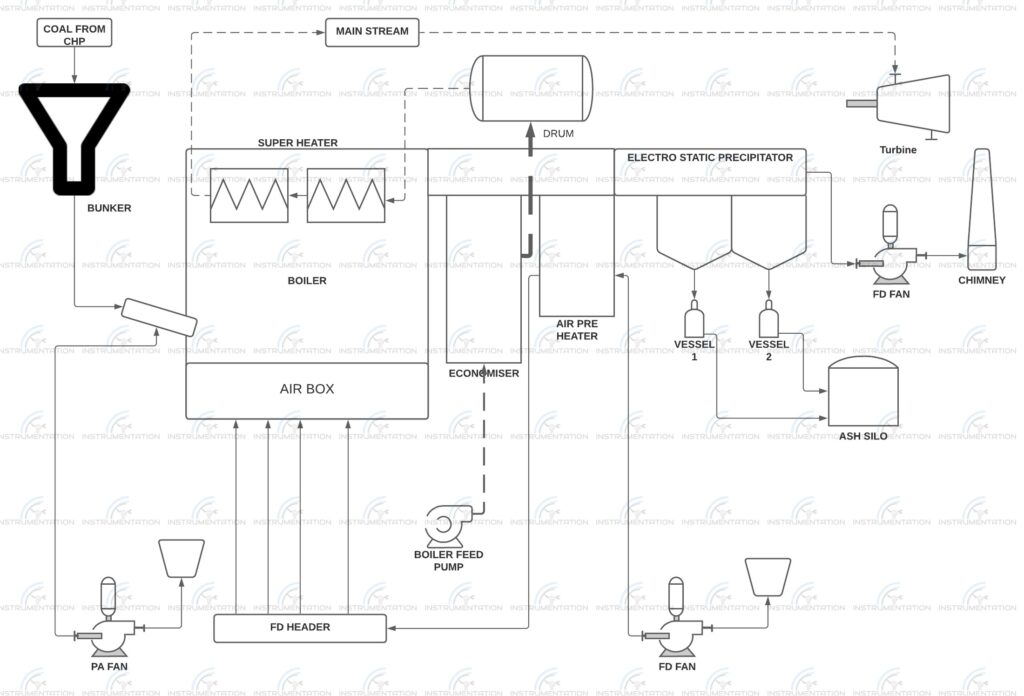

We can’t able to imagine a life without electricity now a day. There are many methods available nowadays to produce energy. The coal combustion method is carried out for many years and used still now with advanced technology .The Thermal power plant commonly consist of four major units.

- Boiler

- Turbine

- Ash handling plant

- coal handling plant

- De mineralized plant

If you take any boilers you will see all these units. And some other units like the auxiliary boiler unit for producing steam during startup are used in high capacity boilers. And flue gas desulphurisation units are used to remove the harmful content from the flue gas. But in most of the coal based power plant is operational with the above major units

Boiler

The boiler is the place where the combustion of fuel takes place. And the heat energy is used by the water tube and heater coils to generate steam. The generated steam will be transmitted to the turbine unit for power generation. There are several pieces of equipment and machinery involved in building a boiler.

- Primary air fan

- Forced draft fan

- Induced draft fan

- Economizer

- Air preheater

- Drum

- Coal feeders

- Bunkers

Primary and forced draft Fans

To create a combustion air is one of the fuel, by mixing an equal ratio of coal and air combustion is maintained throughout the process. The air is preheated by the means of an air preheater attached to the flue gas path. The primary air fans are used to mix with the coal and inject into the boiler to undergo firing. And forced draft air is given continuous to maintain a combustion process.

Induced draft fan

The id fan helping to get the flue gas out of the boiler. The flue gas produced after the combustion process pass through the economiser, APH and ESP finally kick out but ID fan to the chimney. To preserve the environment nowadays flue gas desulphurisation(FGD) unit are constructed to remove the harmful substance from it before exposing to the atmosphere.

Economiser

Before feeding water into the boiler they are preheated to increase the efficiency of producing steam. The economiser is placed at the flue gas path to transfer the heat from it. By this heat exchange, the water already start to produce steam before entering the boiler.

Air preheater

The forced draft fan air is preheated by the flue gas. Thus increasing the temperature of the air to use in the combustion process. And by this method, the flue gas temperature is also reduced significantly.

Drum

A drum is a place where the water and steam are separated. The steam separated will be routed to the superheaters coil to produce saturated steam. The drum level control is very important in a power plant as its level has to be maintained at 50% all the time to operate a plant safely.

Coal feeders and bunkers

The bunker store the coal needed sufficiently to run a boiler. With the full loader bunker, a plant can operate for half-day. From the bunker, the coal is needed ito a boiler using coal feeders. There are many types of feeder available used according to the application and capacity. The coal from feeders is injected directly into some boiler and some crushes in the mill before feeding it purely depend on the application.

Conclusion

Thus now you may get a rough idea about the power plant and boilers. In future will describe the detailed process of higher mega watts power plant. Please leave the comment in description for any additional information.