Pneumatic Ash Handling System

In a thermal power plant, ash handling systems play a vital role. The coal after burned inside the boiler converted into ash needs to be disposed of the boiler without exposure to the environment. Fly ash is a lighter particle its easily carried out by wind creates pollution. And it is harmful to the workers if they inhale it for a long period. It may lead to a severe health condition. So handling fly ash is a challenging task.

The ash generated after the combustion process flow towards the electrostatic precipitator crossing the economizer and air preheater area. The electrostatic precipitator consists of the charged plate that makes the ash stick to the plate and when the plate gets discharged the ash will get collected in the hopper attached below.

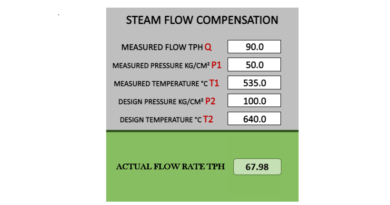

The diagram will help you to get a clarity about pneumatic conveying system take place in the industry

The hopper vessel is protected by the mean of the level switch to alert in case of a high level due to conveying problems. The conveying vessel consists of the inlet gate valve and a dome valve for isolation. Both the valve is operated by the means of a pneumatic cylinder. And the neck of the vessel has sealed using air to avoid ash and air get the return back to the hopper in case of any defect in the seal kit or valves. The seal pressure is taken as one of the interlocks to start a conveying system. The purge valve help to kick back the ash to the silo and this valve will operate only after getting close feedback from the dome valve. And finally, the conveying line is provided with the pressure switch to find out the blockage of the line due to ash.

Mode of operation

- Timer mode

- Probe mode

In the timer mode, the conveying will start in sequence as per the set point. When all conditions are satisfied the conveying will keep on going forever interval set. The following sequence will happen as followed.

1. If the level is normal, the seal pressure switch is healthy, and conveying blockage pressure switch not activated.

2. If all above permissive satisfied, OPEN command will be given to the inlet valve SOV from the controller(PLC or DCS).

3.In a second’s OPEN command is fed into the dome valve SOV.

The ash will now get collected in the conveying vessel.

4.After few seconds CLOSED command is given to both inlet and dome valves.

5.Once the seal pressure normalized after the closing of the dome valve. The OPEN command is fed into the purge valve.

The service airline connected to the purge valve will push the ash to the silo. This is how a complete conveying cycle takes place.