Motor Auto Start-Stop Control Logic

In industry, there are many parameters to control. So the operator can’t able to keep on monitoring every process. Most of the process is control by the automation system itself. Let’s see how a motor auto start stop by an simple logic.

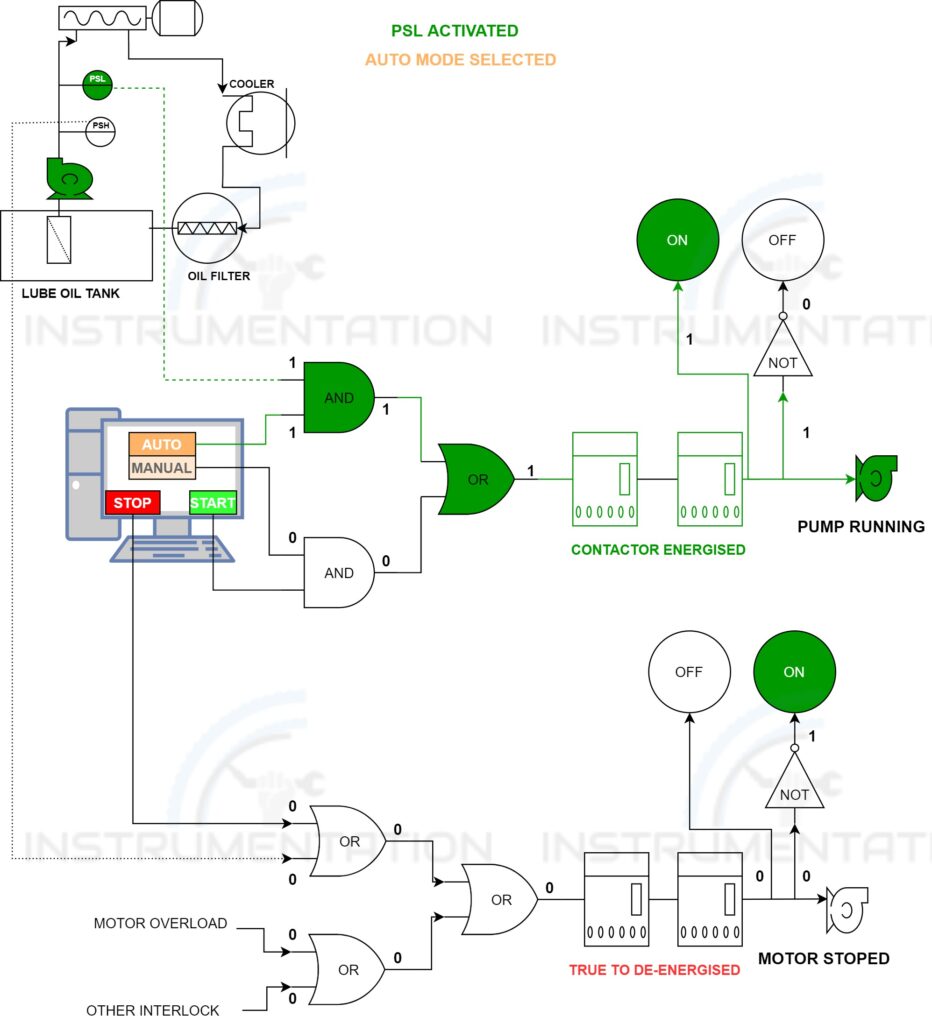

In the below example the pump is supplying lubrication oil to the equipment. And the lube oil pressure has to be maintained between 2 to 4 bar. The low switch(PSL) will be acted when the pressure drop below 2 bar and the pump will be started automatically if selected in auto mode.

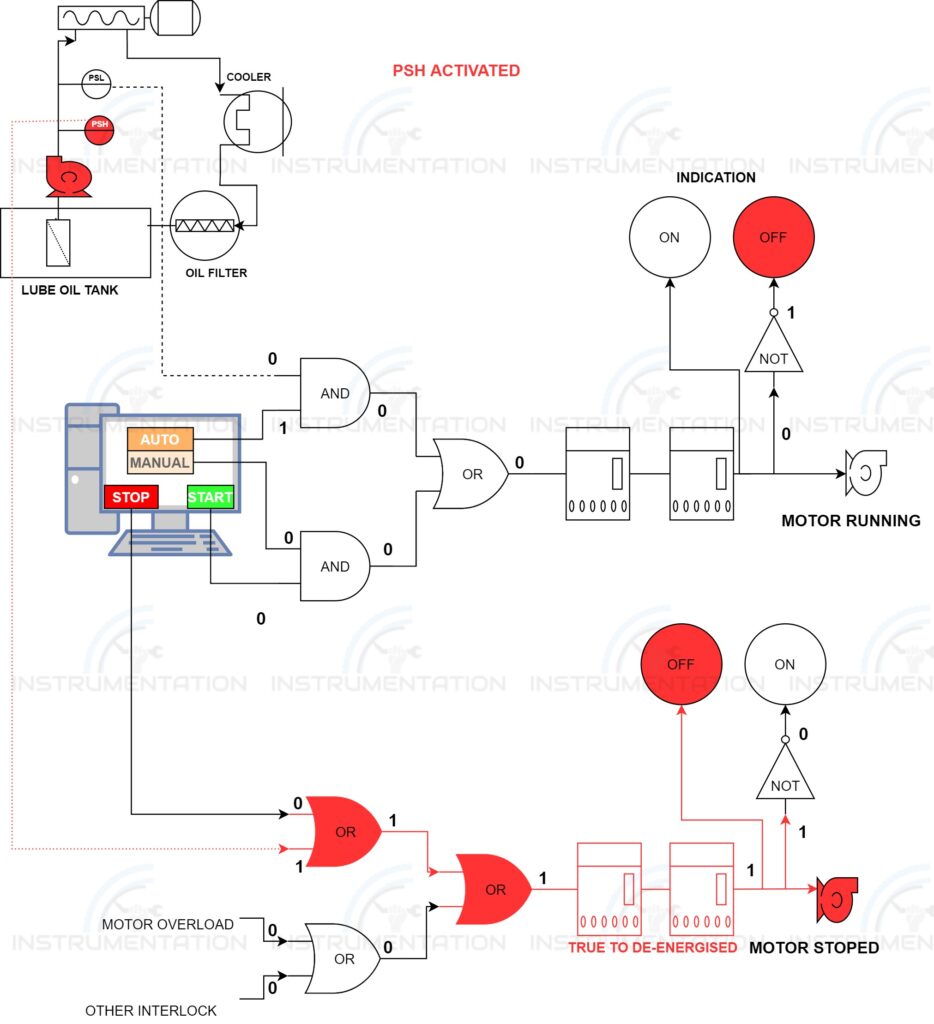

Similarly, when the pressure reaches 4 bar, a High switch(PSH) will be acted and the pump will be stopped automatically. Thus pump will be kept on operating until any disturbance like motor overload and other interlocks according to the application.

As shown in the example the low-pressure switch got activated, As the pump is in auto mode the logic became true and the contactor on the respective panel side will get activated. By the means, the pump will get started to run and the feedback indicator lights up with running feedback.

And after the pump keeps on running for some time until the high-pressure set point reached. When the PSH is activated the logic will de-energise the contactor. And the pump will get stopped. And this cycles continues until it gets interrupted by any interlocks linked to the logic.

Thus this is the simple example how motor auto start stop in industry.