Loop checking procedure of transmitter

The instrument loop checking is one of the main activities carried out before the commissioning process. The loops are checked if all connection are exactly connected as per the design document.

Before starting the loop checking procedure check the following.

1.Check the polarity of the transmitter and the proper cable tag is installed with polarity.

2.The cable tag has to be installed as per the cable schedule.

3.Check the unit displayed is as per the documents. And the same in both SCADA and instrument side.

4.Using Hart communicator check the following Parameter

- Tag number

- Check proper URV and LRV

- Correct units

- Damp value

- Alarm setpoint.

After checking the details, start the loop checking of the loop.

https://instrumentationbasic.com/pressure/5.Stimulate the transmitter by injecting the mA at the field end, and check whether the correct value is displayed in the SCADA display. For the trip, the loop uses the calibrator to inject the pressure according to the range. And undergo the five-point method and note down the reading in the report. If any error occurs note down in the the punch list to recalibrate the transmitter.

6.Verify the calibration and check the calibration label is visible in the instrument. And also note down the validity to perform a calibration after expiry.

It is better to note the punch list during loop checking, so we can save time during the entire process

7.Check the cable tag, instrument tag plate are matching.

8.Check whether the cable is properly legged throughout the loop in the field, junction box and marshalling cabinet.

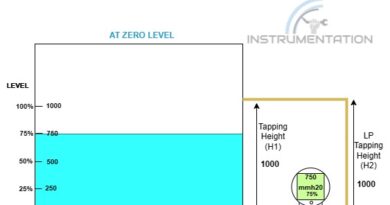

9.Infield check whether the transmitter tapping is connected properly as per the hookup diagram. Check the flange bolts are tight properly ifelse note down in the punch list.

10.check the mounting of the transmitter and impulse line. And check the proper instalment of the drain line as per the documents.

By following the above procedure it will be easier for the maintenance department to avoid major problem during startup. The above procedure is not the standing loop checking procedure, but it will save a lot of time during the commissioning process and reduce the problems.