Live zero and Dead Zero

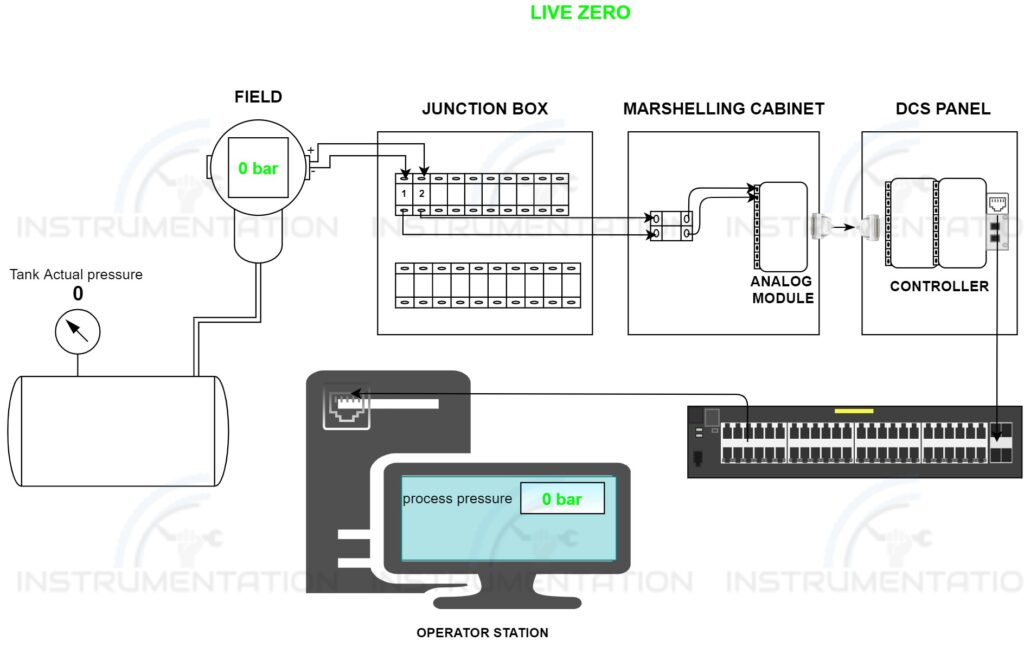

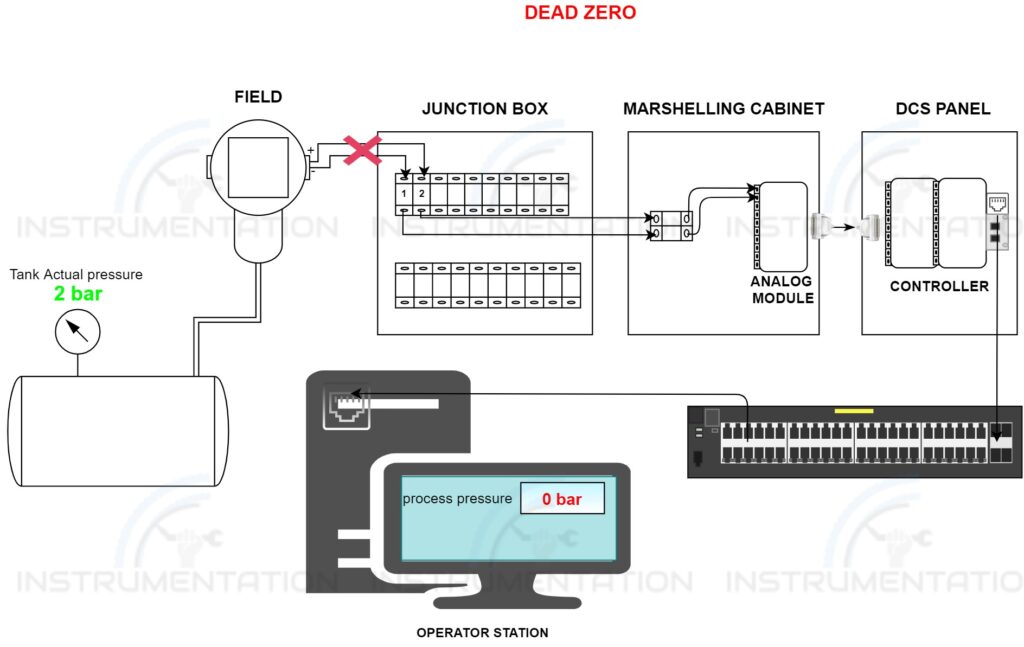

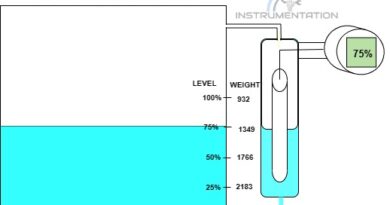

This is one of the commonly asked interview questions. The image below will explain to you what is the difference between these two things. As we know in the industry the command and feedback or transmitted and received by the means of an electrical signal. The 4 to 20 mA is used as a standard range throughout the world for scaling the signal. In this (4) the minimum value also known as live zero and (20) is the maximum value.

For example, the signal to the Control Valve got disconnected due to a fire accident. In such case the cable got damaged in between, the circuit will become open. It will lead to milliamps values dropping to 0. This point is referred to as Dead Zero. And similarly during normal conditions zero percentage command, given to the control valve. And the valve operates according to the command and reaches the zero positions (close), this point is referred to as Live Zero.

Therefore the lives zero is used to determine the minimum or zero value of the process variable. And the dead zero is used to denote the did signal drop or cut due to any following reasons like cable damage, cable removed, loose cable connection, etc. Which leads to a drop in current value.