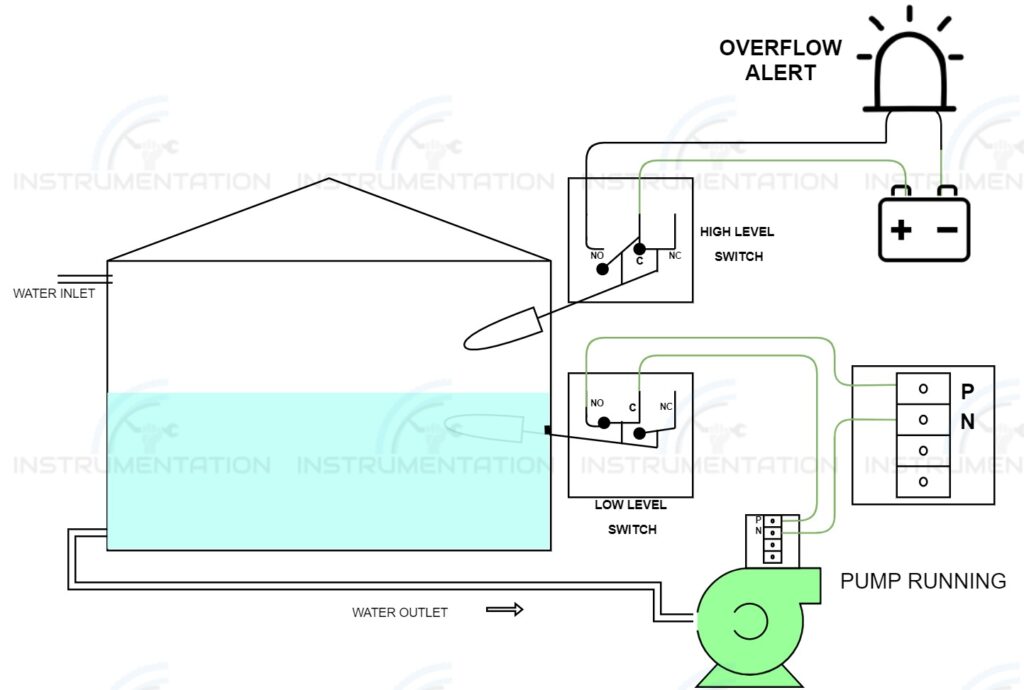

Level switch connections

The switches are used in the industry to notify the status of the process or equipment by the means of a digital signal. It’s alert us by the means of alarm, annunciator and acts immediately if the process control limit is reached beyond the point. Let’s see how the level switch used as interlocks to turn on or off the equipment, which helpful for us to take action according to that.

As you see in the diagram the tank is continuously filled with water and the pump is transferring the water from the tank to the utility. Here we have installed a two-level switch to enhance the safety of the motor and to avoid overflow of the tank. For the basic understanding purpose, I have used only two interlocks after this you can easily able to identify how complex interlock is implemented.

Normal operation

During the normal operating condition, the water from any source keeps on filling the tank. And the pump will be shifting water from the tank to other places. And in case the flow of inlet water reduces or stopped the level will begin to drop. At such a condition, once there is no level to pump the water, the motor will be kept on running at an empty load to avoid that the low switch is taken as an interlock.

The low switches contact are normally connected to Normally open contact. Here we need to operate the pump continuously during the normal level. And if the level reached the low limit the pump has to be stopped. So the current supply is switched by giving the phase through the low-level switch. When the level rises the low switch will get acted changing the contact from Normally open to Normally closed status. And hence the circuit got closed the current flow from the power source to the motor and hence the motor keeps running.

Low level condition

In case the inlet water supply gets stopped due to any reason. The pump keeps on pumping the water out of the tank and the level begins to reduce. If the problem is not solved then at some point the level of the tank will reach low. Hence the low switch already gets activated get released. Hence the phase of the motor flowing through the low switch gets disconnected and the pump gets stopped immediately. And the pump will be started only after the level rises and activate the low switch again. This is how the equipment is the start/stop in the industry using switches.

High level switch

Similarly, if the pump gets stopped due to any failure the level of the tank keeps on raising. And it may overflow if there is only an inlet of water. To notify us of the high-level switch is installed and if the level reaches the float of the switch. By lifting the float the link attached to that will change the contact from NO to NC. Similarly, The lamp positive supply will flow to the alarm lamp only when the contact is in close condition. And when the level begins to reduce the float will be back to normal and hence the supply to the lamp got disconnected.

Hope you have to understand with the help of a contact in the switch we can able to drive other equipment according to our needs. The switch comes with two or more contact even with one switch we can able to control different equipment. In the high switch overflow alert is used as one can’t act and on another contact can be used to stop the inlet water. Thus switches play a major role in process control.