Hydraulic Cylinder

A hydraulic cylinder is used in the industry which uses the linear motion of the piston rod for several operations. The linear motion of the piston is used to drive a valve where higher pressure is required. And it is used in the lifting of parts in machinery like stacker-reclaimer. And you may see in many vehicles like diggers and trackers the moving of arms, lifting, etc, the main part is played by this hydraulic cylinder. In this article, you will learn the basic operation of how a hydraulic cylinder works.

The following equipment is used along with a hydraulic cylinder for safe operation

- Accumulator

- Solenoid Valve

- Flow Control Valve

- Pressure Relief valve

- Hydraulic Pump

- Hydraulic Skid

As these are some of the basic equipment used and in order to understand this clearly, you need to have a basic understanding of how other equipment works. Lets me explain how the hydraulic cylinder operates

The hydraulic cylinder normally consists of two openings for hydraulic oil to enter. If the oil is applied to the bottom port of the cylinder then the pressurized oil will push the rod the piston will extend outside.

At this state, the piston extended outside by applying pressurized oil to the port near the piston end the extended piston will start to retract inside the cylinder. The oil already present inside the other end of the cylinder will start to drain through the same port used for entry.

In this state, if you want to again extend the piston apply pressurized oil to the end cap port. The piston will extend outside, and the oil present inside the other side will make its way back to the reservoir through the same port.

Now you may wonder how the entry and exit through the same port. Here the Solenoid valve plays a main role. It helps to route the hydraulic oil to the desired location as per our application. The valve is actuated by the solenoid coil which drives the valve piston inside to change the ports.

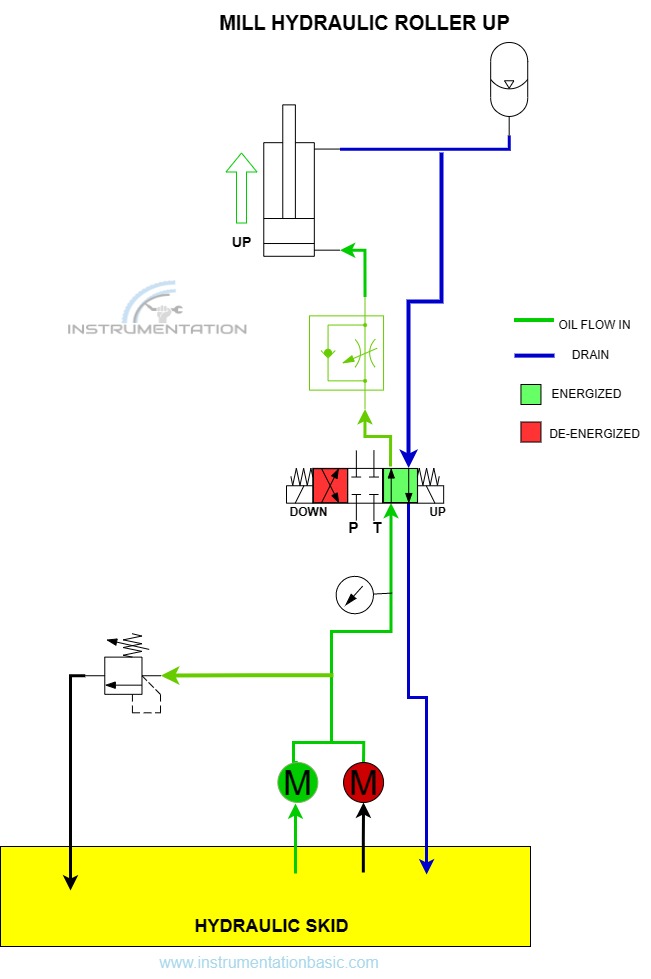

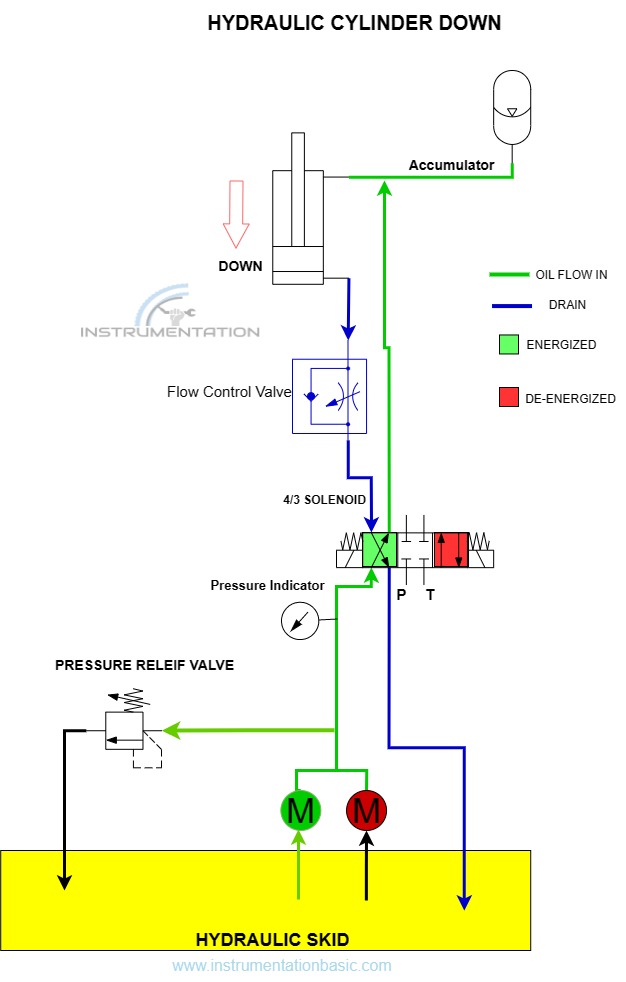

Let’s consider one example of how the cylinder operates, the diagram below helps you to get a clear idea.

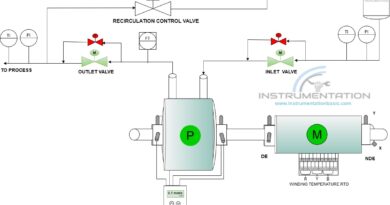

Hydraulic Skid

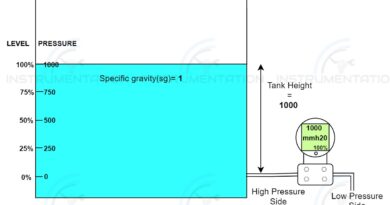

It is nothing but the tank which is used to supply oil by the mean of the pump to the cylinder through a solenoid valve. And the oil returned from the cylinder will get drained through the sov again through the skid. And the hydraulic Skid is protected by several instruments like

- Temperature sensors

- Level sensors

- Pressure Instruments

- Flow sensors

This help to safeguard the pump against any damage. If there is no level pump will run on an empty load, which is not safer for the pump. Similarly, a temperature switch or sensor is installed to monitor the temperature of oil in the tank, in case the return oil cooler fails the temperature of the tank will increases.

Pressure Relief Valve

A pressure Relief Valve is provided to drain immediately if the pressure of the pump reaches above the set point fixed. Any pressure above the limit will make the valve open to decrease the pressure and the valve get closed automatically if the pressure drops. It helps to prevent pressure above the limit from entering the cylinder.

Solenoid Valve

It is nothing but the valve operated by energizing the coil which moves the plunger inside to change its port. As you see in the diagram it’s a 4 port 3 position solenoid valve called 4/3 SOV. As you see in the diagram it has 3 position

- Middle position – All ports closed, oil from either side will not pass to another end

- Right and Left Position – The port will changes once gets energized, the flow direction is shown in the diagram

Up operation

In order to open the cylinder the sov towards the right side will get energized and oil will flow through the control unit and pass inside and operate the cylinder.

Down Operation

As the down sov got energized the oil inside the down portion of the cylinder will get drained back to the oil tank through the sov and at the same time pressurized oil passed into the top port of the cylinder pushes the piston down to complete the operation. The diagram below helps you to understand.