DRUM LEVEL CONTROL METHODS

SINGLE ELEMENT CONTROL

This Drum level control uses only one measured variable, DRUM LEVEL. In this system drum level is measured and controlled by adding feed water to compensate for evaporation. Single element control is applied to the boiler with solely changing steam demand and with minimal occurrence of Shrink and swell.

APPLICATIONS

- Plants with a stable load.

- Initial startup and up to 30% load of boilers with varying load

TWO ELEMENT CONTROL

This uses two measured variables. Steam flow signal is used as feed forward signal anticipating change in drum level on steam flow change.

1 .DRUM LEVEL (feedback control)

2 .STEAM FLOW (feed forward control)

APPLICATIONS

- Plants with varying load, but with good feed water regulation.

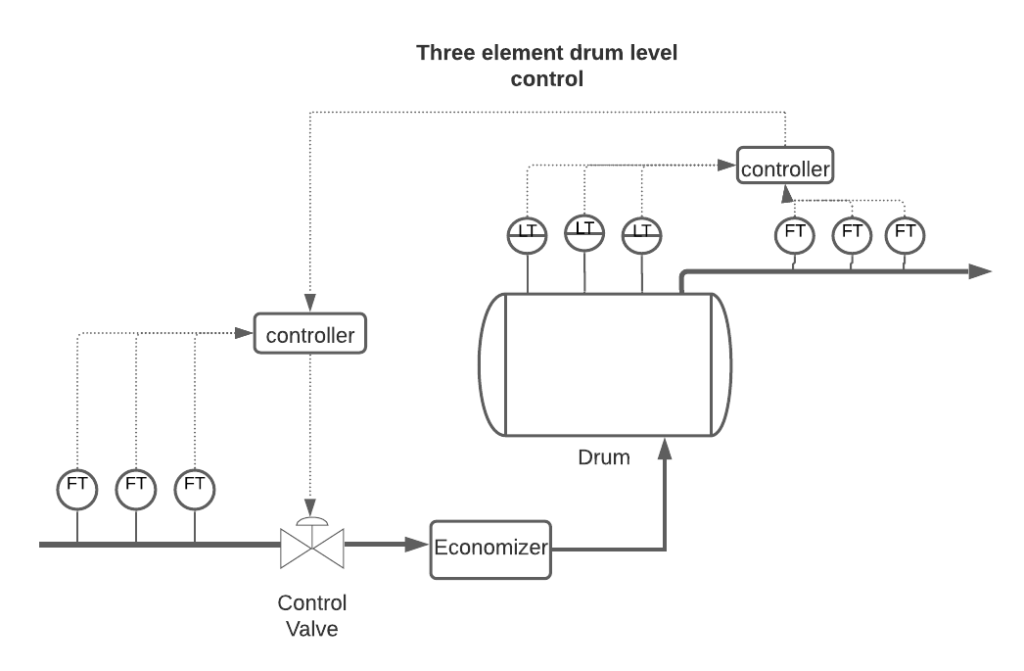

THREE ELEMENT CONTROL

In this system three variables influence feed water valve position.

1.DRUM LEVEL

2.STEAM FLOW

3.FEED WATER FLOW

Three element control systems are capable of Providing close adherence of the drum level to the setpoint under steady conditions. And Providing tight control of mass balance during transient load changes. This control system works well with feed water systems which exhibit variable feed header to drum pressure differentials, as feed water flow is measured & controlled. The Linear relationship between feed water flow and steam flow reduces load changes on level, under conditions of flow change. In other words, For one kg of steam leaving the drum one kg of feed water is added. As a result, liquid level remains relatively constant.

APPLICATIONS

Three element controls is suitable for loads exhibiting wide and rapid changes,This type of control is widely used in all industrial/utility boilers.