Control valve basics

The control valve is a final control element used in the industry to control the process parameters like pressure, temperature, flow, and level.

Working and types

The control valve is classified based on its characteristics and actions. The control valve is operated by giving pressurized air through one side of the case. The air pushes the diaphragm aligned by the spring on the opposite side and the valve connected to the actuator stem operates by this method. When we cut off the air supply the valve will be back to its position by the spring tension. Based on the control valves are designed in two ways if a pneumatic supply is given on top of the diaphragm case it’s is called Air-Fail open valve and through the bottom, it’s called the Air-Fail close valve. In addition, control valves are classified into three types according to the control characteristics they are linear, equal %, and quick opening/closing.

Important components

- Positioner

- Air filter and regulator

- Volume boosters

- Actuator body

- Airlock relay

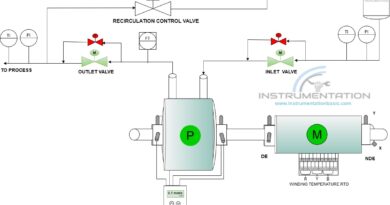

Actuator body

The actuator body consists of components like actuator stem, spring, diaphragm, diaphragm plate, stem connector, local scale, etc. These are the basic material found and they vary in size. The actuator stem is the central part of the unit that connects the plate with a diaphragm on the top and the valve stem at the bottom couples together by using a stem connector.

Positioner

The positioner is the brain of the control valve without this actuator is just an on/off valve. The positioner consists of a set of electronic components to process the real-time control action. Some List of parts is given below.

- Display unit

- Analog control unit

- I/p converter(current to pneumatic)

- Pneumatic relays (single or double-acting)

- Feedback encoders

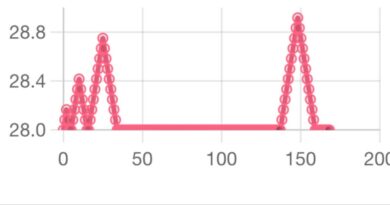

The signal from the control room is processed and converted into a respective pneumatic signal of range 0.2 to 1 kg/cm2 in the I/p converter. In addition, the output air is led out of the port through the relay assembly. The valve will get operated and the position of the valve is sensed by The encoder.

Air filter and regulator

It’s used to filter the dust and moisture content to enter the positioner and control valves to avoid malfunction. Also, it comes along with the capability to regulate the supply pressure as control valve supply pressure varies according to their size and capacity.

Volume boosters

The volume booster is used in large capacity valves to boost the air volume to open/close the valve quickly. Also, the airlock relay is used for safety, in case the air supply failed due to the trip of a compressor unit or instrument airline got damaged, such a situation airlock relay connected on the output line will get shut down. It will hold the valve position for some time, helps us rectify the problem without major process interruption.